Turning

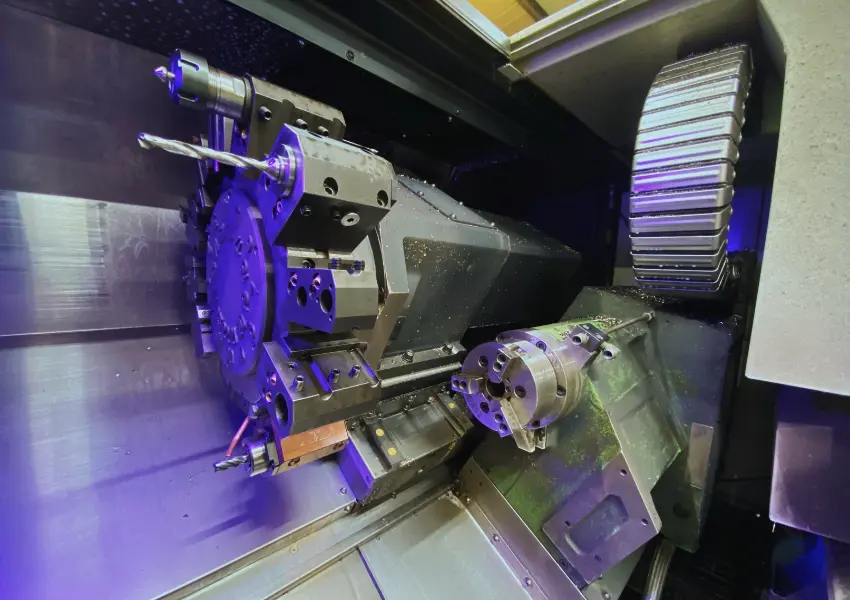

At BIL Engineering, our turning capabilities are powered by fully automated bar-fed lathes with live tooling and sub-spindles, enabling us to handle specialised and complex tasks with exceptional precision and efficiency. The automated bar-fed system ensures continuous production with consistent material feed, ideal for small and large volume runs, while minimising errors and enhancing product quality.

Live tooling allows us to perform simultaneous milling, drilling, and turning, reducing the need for multiple setups, and significantly boosting operational efficiency. The sub-spindle enables us to machine both ends of the workpiece in a single operation, reducing production time and ensuring perfect alignment for maximum precision.

These advanced technologies allow us to produce intricate, high-quality parts tailored to your specifications, meeting the most demanding industry requirements with unmatched consistency and reliability.